Unvented hot water cylinders aren’t really the most exciting part of a home, but they do a lot of work without you noticing. Until, of course, they don’t. Many people forget these systems even have safety parts that need checking. A bit of regular maintenance goes a long way, and it’s usually easier and cheaper than dealing with a breakdown at the worst moment.

What Is an Unvented Cylinder?

Basically it’s a hot water tank that runs off mains pressure instead of using a tank up in the loft. Because the water is fed straight from the mains, you get better pressure at your taps, showers etc. That’s why newer builds and refurb jobs tend to go for them. Also, they work very well with air source heat pumps which heat water differently (lower temps but more efficiently).

The main point is: they store hot water, do it under pressure, and have a safety kit inside that needs attention.

Why Servicing Matters

A lot of people think “it’s working fine so why touch it.” But unvented systems aren’t quite like a normal tank. They’re pressurised, and if a valve or expansion vessel stops working right you can get problems like:

- Water coming out of the discharge pipe (which people often ignore or don’t even notice)

- Higher energy bills

- The water not heating properly

- Strange noises from the cylinder cupboard

- Safety concerns if something critical sticks

Most of the time issues are tiny if caught early, but a pain if not.

What Happens in a Maintenance Visit

Different engineers have slightly different ways of doing things, but generally they’ll go through the key parts of the system. It might look like a quick job, but it’s more detailed than it looks on the surface.

Visual check

Look around the cylinder: any rust marks, damp patches, insulation slipping or gone, that kind of thing. Pipework too. Even a small dribble from a fitting can turn into something more annoying.

Expansion vessel

This one often gets overlooked by homeowners. It’s basically what takes up the pressure when water gets hot and expands. The engineer will check the pressure in the vessel and pump it up if needed. If it’s flat, the system won’t behave properly.

Safety/relief valves

These protect the cylinder from too much pressure or heat. The engineer normally tests them (sometimes they lift the little lever but not always if the valve is older). Also checking that the discharge pipe isn’t blocked or restricted, which does happen.

Thermostat and temp settings

A wrongly set cylinder stat can make your system run badly or too hot. Usually around 60°C is the mark. And if you’ve got an air source heat pump heating the cylinder, the settings matter even more because heat pumps don’t run at the same high temps boilers do.

System pressure and heat source

If the cylinder is tied to a boiler or a heat pump, they’ll check the interface between the two. For heat pumps especially, correct flow rates and temps really matter to efficiency and performance. If something’s off here, your running costs go up without you realising.

Insulation + pipes

Any exposed hot water pipes should be insulated. Lots of houses have missing bits because they’ve fallen off or got removed during repairs. The engineer will usually mention if something needs sorting.

Notes + record

Even though it sounds boring, a written record helps. It’s proof of servicing (some warranties need it) and it highlights small faults before they turn into real problems.

How Often Should You Do Maintenance

Most manufacturers say yearly. And honestly that’s usually enough. If you’ve got a busy household with 2 or 3 showers running most days, or your cylinder is paired to an air source heat pump, doing it regularly is definitely a good idea.

Some people stretch it to every 18 months but that’s pushing it if you want efficiency and reliability.

How You Can Help Look After It Yourself

You don’t need training for every little thing. A few bits you can do:

- Keep the cylinder cupboard tidy (you’d be surprised how many cylinders are buried behind boxes)

- Listen for new noises: banging, rumbling, hissing

- If the hot water starts dropping in temp or pressure, don’t ignore it

- Occasionally glance at the discharge pipe outside to see if it’s dripping

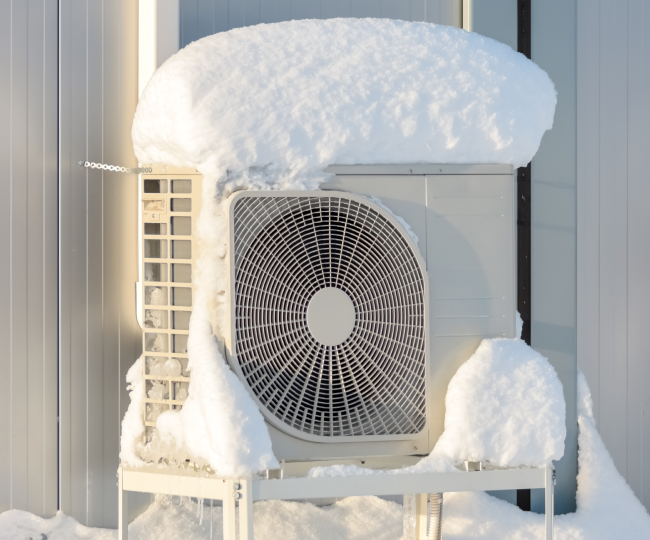

- If you’ve got an air source heat pump, keep the outside unit clear of leaves and clutter

None of that replaces servicing, but it helps keep everything running smoother.

Why Use a Proper Unvented Cylinder Engineer

Unvented cylinders are legally required to be serviced by someone qualified for unvented systems, because of the pressure and safety elements involved. DIY is definitely not recommended with these.

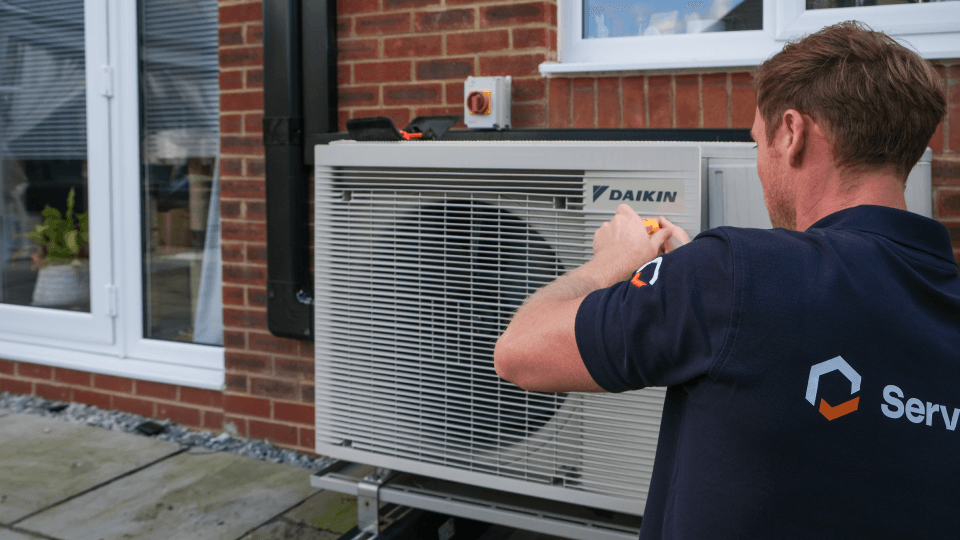

Also if your setup includes an air source heat pump, it’s even more important to get someone who knows both systems. A small mismatch or wrong setting can make a heat pump run pretty badly.

Wrapping Up

Unvented cylinders don’t need tons of work, but they do need some care. A quick yearly service keeps things efficient, safe and reliable. It’s cheaper than a big repair, and better than standing in a cold shower wondering why the hot water decided to quit today. If you can’t remember the last time yours was checked, it’s probably time.

Schedule Your Heat Pump Service Today

Don’t wait until efficiency drops, or your pump encounters issues. Investing in routine maintenance for your air source heat pump is the best way to keep your household energy-efficient, cosy, and cost-effective year-round.

Get in touch with our professional servicing team today to schedule your appointment. With extensive experience in heat pump servicing and home energy solutions, we’re here to help you stay warm, save money, and protect your investment.

Maintain your heat pump, and it will reward you with years of efficient and reliable performance!